CHOOSING THE BEST INTERIOR DOOR FOR YOUR HOME

When building your new home, there are many selections to make, and some of those choices are more important than others and require much consideration. One of those decisions that most homeowners don’t give much thought to is the type and style of interior door; however, with the right door, you can maximize the functionality and appearance of your home.

When choosing an interior door, there are questions you need to answer before picking out your door, such as, do you want a molded or flush door, what is the door’s function, and do you need a hollow core or solid core door?

Molded vs Flush

When choosing interior doors, the first decision you need to make is the door type. The type of the door can be either molded (panel) or flush. Molded doors are constructed by pressing or molding two panels (skins) together to form a particular layout. The skin, or face, of the door is a 1/8″ molded hardboard that is available with a pre-primed smooth or textured painting surface; molded doors cannot be stained. Opposite of molded doors are flush doors. Flush doors are completely smooth with no design and manufactured with plywood skins or Medium Density Fibreboard (MDF) fixed over a light timber frame. Flush doors are available as solid or hollow core.

Door Function

Now that you have selected a door type, you need to consider the purpose of the door. There are several door styles that offer different functions, including bi-fold, bypass (barn door), pocket, standard, or custom-sized doors. Bi-fold is a popular option for closets when space outside of the closet is tight. Sliding bypass doors are typically used in rooms that are short on floor space or used to separate one section of the home from another. Pocket doors disappear into the wall and are ideal when there is no room for a swinging door, a need to save space, or a desire for a minimalist look. However, standard doors are what most homeowners will select for most of their home’s interior doors.

Hollow vs Solid

Once a door type and style is selected, you need to decide about its construction. Doors are made with a Solid Particle Core (SC), Hollow Core (HC), or Solid Mineral Core (MC). Solid core doors provide the weight and feel of an all-wood door. The advantages of solid core doors are added security and reduced sound transmission due to its solid, heavy construction.

Hollow core doors are much lighter weight; however, they are an economic alternative to a solid core door. Mineral core doors or fire-rated doors incorporate a mixture of noncombustible minerals and are only used when a fire rating is required, such as the door that separates the garage from the dwelling. Typically, homeowners will only have to decide whether to install solid core or hollow core doors for their remaining interior doors.

What are Solid Core Doors?

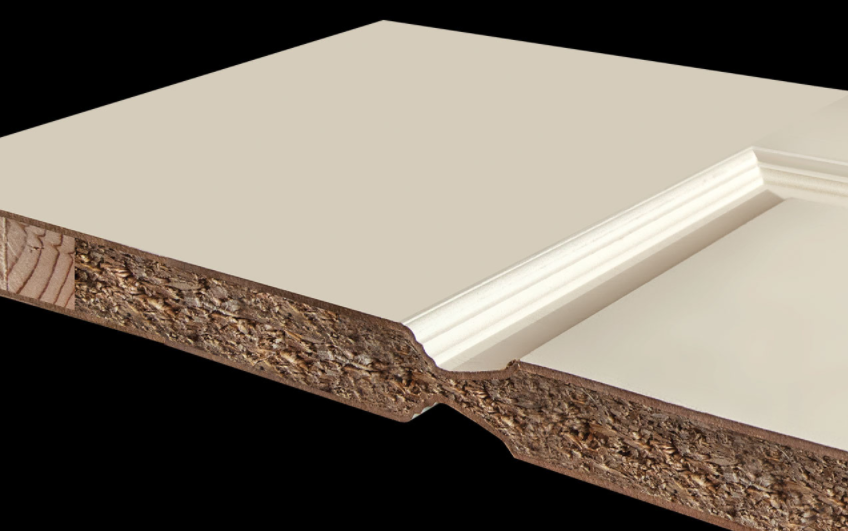

A solid core flush door is manufactured by applying two sections of plywood to a solid core piece. A solid core molded door features a frame which includes vertical wood stiles to accommodate hinges and door hardware and horizonal wood rails to provide a solid edge at the top and bottom of door panel. On a molded door, the core is routed out to match the layout of the door skin. A solid core molded door is assembled by pressing and gluing the skins, frame, and core together.

Solid core doors provide the durability, sound insulation, and look of a solid wood door without the weight or high price tag. Solid core doors are ideal for rooms where you might want more privacy and sound insulation, such as bedrooms, bathrooms, and home offices. While solid wood doors tend to expand or shrink with moisture or temperature changes, solid core doors resist these fluctuations and will maintain their shape over time. In many ways, the solid core door merges the benefits of a solid wood door with the benefits of a hollow core door as an intermediate option. However, solid core doors aren’t without their shortcomings. Solid core doors are heavier than hollow core doors, since the center of the door is solid, and they can be hard to repair, for example, damage done by door stops. Click here to watch how solid core molded doors are manufactured by Steves & Sons.

Solid Core Door Pros:

Affordable option to solid wood doors

Mirrors look and durability of solid wood doors

Typically paint-ready

Resists fluctuations due to temperature and moisture

Durable and heavy-duty

Ideal for reducing sounds

Excellent insulator

Solid Core Door Cons:

More expensive than hollow core doors

Difficult to install due to weight

What are Hollow Core Doors?

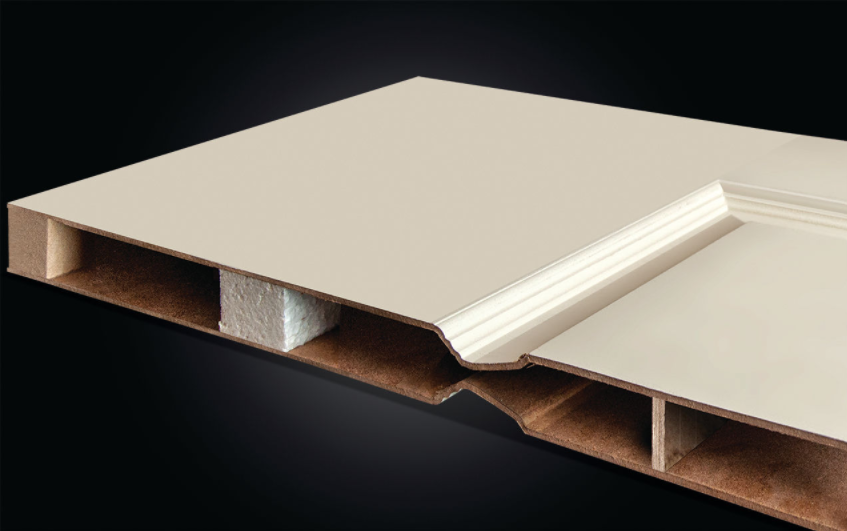

A hollow core flush door is completely smooth with plywood or Medium Density Fibreboard (MDF) fixed over a light timber frame, and the hollow section is filled with a cardboard core material. Hollow core molded doors feature a frame which includes vertical wood stiles to accommodate hinges and door hardware and horizonal wood rails to provide a solid edge at the top and bottom of door panel. The core of the door is filled with blocking which is a cardboard lattice or a honeycomb material that supports the door skins. A hollow core molded door is assembled by pressing the skins, frame, and core together.

Hollow core doors are easy to install, lightweight, and cost effective, making it simple for one person to handle and install the door. Hollow core doors are perfect for closet doors and pantry doors, where no sound insulation is necessary. However, hollow core doors don’t insulate sound very well, and they are not very durable. If they’re damaged, replacement is generally the only option.

Click here to watch how hollow core molded doors are manufactured by Steves & Sons.

Hollow Core Door Pros:

Lightweight

Easy to install

Cost effective

Minimal expansion and contraction

Pre-primed for painting

Hollow Core Door Cons:

Not very durable or secure

Does not insulate sound

Lower quality feel

What Langbeen Builders Offers Its Clients

Langbeen Builders offers its clients both hollow core and solid core molded door options — flush doors are not offered as a selection but could be installed at a client’s request. Hollow core doors are the standard selection and are included as part of the overall building package. Langbeen Builders installs interior doors from Steves & Sons, and clients can choose from three hollow core door layouts, including Colburn Smooth, Rochele Smooth, and Connelly Smooth. In addition, Langbeen Builders offers molded doors with the Colburn, Rochele, and Connelly layout but with a solid core; however, these doors are considered an upgrade.